Revolutionizing Automotive Solutions with Automatic Painting

In the ever-evolving landscape of the automotive industry, staying ahead requires more than just innovative designs and superior engineering. It calls for the integration of advanced technologies that enhance productivity, reduce costs, and improve the overall quality of products. One such technology making waves in the automotive sector is automatic painting.

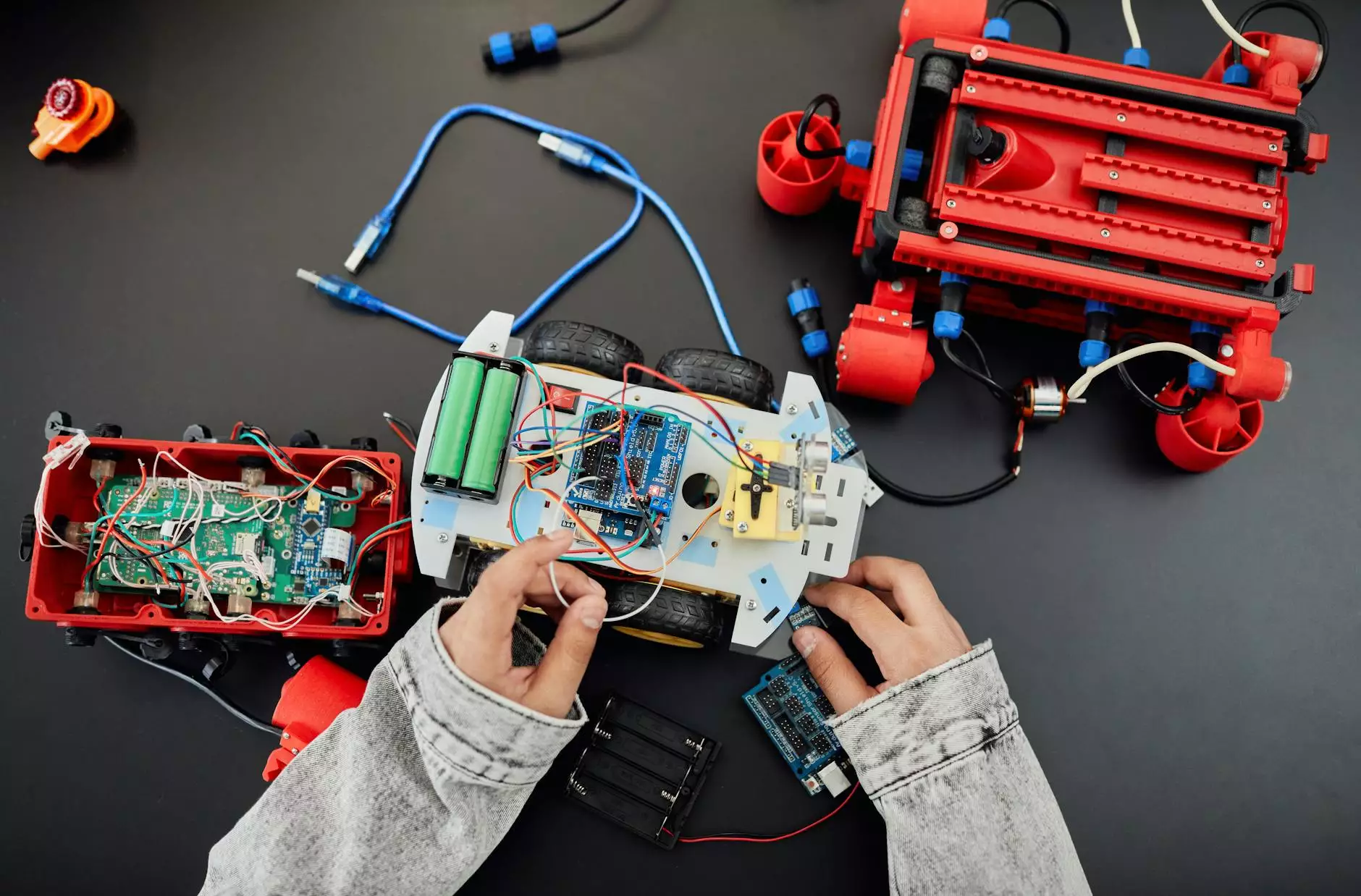

Understanding Automatic Painting

Automatic painting refers to the use of automated systems and machinery to apply paint to vehicles or parts of vehicles. This method streamlines the painting process, ensuring consistent results while minimizing human error. The implementation of automatic painting systems goes beyond mere convenience; it encapsulates a philosophy aimed at improving the manufacturing process.

The Evolution of Painting Technologies

The painting process has evolved significantly over the years. Traditional methods relied heavily on manual labor, which often resulted in variations in quality and output. With the advent of automatic painting technologies, manufacturers can take advantage of:

- Increased Efficiency: Automation drastically reduces the time required to complete painting tasks. An automated system can paint a vehicle far quicker than a team of manual workers.

- Enhanced Precision: Automatic systems ensure uniform application, leading to consistent coating thickness and minimizing the chance of errors.

- Reduced Waste: Automated systems are programmed to use the exact amount of paint needed, resulting in less overspray and waste.

- Improved Worker Safety: By reducing the need for human labor in hazardous environments, automatic painting systems enhance workplace safety.

The Benefits of Automatic Painting in the Automotive Industry

Adopting automatic painting systems within automotive manufacturing brings forth a myriad of benefits that can directly influence the business’s bottom line. Here are some of the most notable advantages:

1. Cost Reduction

While the initial investment in automated painting equipment can be high, the long-term savings justify the expense. Automatic painting reduces labor costs, minimizes paint waste, and decreases the need for rework due to application errors.

2. Superior Quality Control

A significant advantage of automatic painting is the ability to maintain strict quality control standards. Automated systems can be calibrated for precise color matching and coating consistency, resulting in a finished product that meets or exceeds customer expectations.

3. Enhanced Flexibility

Modern automatic painting systems offer flexibility in terms of color changes and design variations. Rather than requiring extensive setups for different paint jobs, automated systems allow for quick adjustments, making it possible to switch between models and colors with ease.

The Role of Technology in Automatic Painting

Automatic painting is not only a setup of machines and robots; it is a sophisticated blend of numerous technologies designed to work in harmony. Key technologies that contribute to successful automatic painting processes include:

1. Robotics

Robot arms equipped with specialized spray guns can perform intricate painting tasks with precision. These robots can move in different directions, allowing for comprehensive coverage of complex vehicle shapes.

2. Computer Vision

Utilizing advanced sensors and cameras, automatic painting systems can detect and assess the surfaces to be painted. This technology ensures that every nook and cranny receives the appropriate coating, enhancing the overall quality.

3. Smart Controls and Software

Modern painting systems rely heavily on smart technology that allows for customization and optimization of the painting process based on various parameters, such as temperature and humidity.

Automotive Paint & Sip: A Creative Fusion

In addition to automatic painting in manufacturing, the concept of Paint & Sip events has gained popularity in promoting creativity and team building within automotive companies. These events not only foster teamwork but can also serve as a unique marketing experience.

What is Paint & Sip?

Paint & Sip is a social experience that combines painting with wine (or other beverages), allowing participants to create artworks while enjoying drinks. Automotive companies can utilize this concept to:

- Boost Employee Morale: Organizing Paint & Sip sessions can be a rewarding break from routine work, encouraging employees to express their creativity.

- Enhance Customer Engagement: Hosting Paint & Sip events can create memorable experiences for customers, reinforcing emotional connections with the brand.

- Promote Brand Awareness: These events can serve as an effective marketing tool, allowing companies to showcase their products in a fun, relaxed setting.

Environmental Sustainability and Automatic Painting

In today's eco-conscious market, the automotive industry faces increasing scrutiny regarding its environmental impact. Automatic painting plays a crucial role in addressing sustainability concerns.

1. Reduced VOC Emissions

By utilizing advanced painting technologies, manufacturers can significantly decrease volatile organic compounds (VOCs) emitted during the painting process. Modern automated systems can efficiently recycle solvents and reduce overspray, which directly contributes to a greener painting practice.

2. Efficient Resource Utilization

Automated painting systems are designed to utilize resources effectively, optimizing paint usage and minimizing waste, thereby reducing overall environmental footprints.

3. Compliance with Environmental Regulations

With increasingly strict environmental regulations, using automatic painting systems helps companies comply with laws and sustainable practices, ultimately protecting the environment and the company’s reputation.

Future Trends in Automatic Painting

As the automotive industry continues to innovate, the future of automatic painting is poised for exciting advancements. Here are some trends to watch for:

1. Artificial Intelligence Integration

The integration of artificial intelligence in automatic painting systems can automate decision-making processes, optimizing the painting procedure based on real-time data analysis.

2. Smart Factories

The automotive manufacturing landscape is moving towards Industry 4.0, where smart factories utilize interconnected devices and systems to increase productivity and efficiency, thereby enhancing automatic painting processes.

3. Customization through Technology

As consumer preferences shift towards personalized products, future automatic painting technologies will likely incorporate enhanced customization options, allowing manufacturers to meet specific consumer demands while maintaining efficiency.

Conclusion

In conclusion, automatic painting is at the forefront of revolutionizing the automotive industry by providing enhanced efficiency, superior quality control, and sustainable practices. As businesses like autocoatindia.com continue to embrace advanced painting technologies, they set the stage for future innovations that will shape the automotive landscape. The fusion of creativity through initiatives such as Paint & Sip only further enriches the culture of innovation and collaboration within the industry.

As we move forward, companies that leverage the benefits of automatic painting will gain a competitive edge in the marketplace, ensuring they not only meet but exceed the expectations of their customers.